In the year 2024, the realm of 3D food printing has witnessed extraordinary progress, with numerous standout printers pushing the boundaries of culinary innovation to new heights. Sitting atop this list is the “Gastronova ProX,” renowned for its impeccable precision and unparalleled versatility. This printer showcases a vast library of recipes and ingredients, empowering users to craft intricate dishes effortlessly. Its user-friendly interface and sophisticated design have endeared it to both seasoned professionals and passionate amateurs alike.

Also read: Innovations in Food Preservation and Waste Reduction

Following in quick succession is the “Chef’sCraft 3D Gourmet,” earning acclaim for its remarkable speed and exceptional efficiency. Leveraging state-of-the-art technology, this printer churns out intricate culinary creations at breakneck speed, catering perfectly to bustling kitchens and catering operations. Its compact form factor and intuitive features render it a pragmatic choice for both commercial establishments and residential settings.

Completing the triad of top performers is the “CulinaryMastermind 3D Deluxe,” revered for its extensive array of customization options and extraordinary flavor profiles. This printer provides chefs with unprecedented control over taste and texture, enabling them to unleash their creativity and concoct unique flavor combinations. Backed by cutting-edge software and top-tier printing capabilities, it’s hardly surprising why the CulinaryMastermind has become a fixture in high-end restaurants and culinary institutions across the globe.

mycusini 2.0

The mycusini 2.0, the next generation of its forerunner, completely transforms chocolate printing with its sophisticated design and vivid color selections. Showcasing a user-friendly 3.5-inch touch color display, it simplifies navigation effortlessly and offers access to a vast template library for creative chocolate designs. Overcoming language barriers is effortlessly achieved with its multilingual interface, obtainable in German, English, Spanish, Italian, and French.

Featuring a spacious print area measuring 90 x 90 x 45 mm and well-lit surroundings, printing precision is guaranteed. Cleaning is made easier with curved edges and a detachable production platform, ensuring a clean experience. Moreover, the printer comes equipped with 3D Choco refills, enabling immediate exploration of chocolate creation.

By becoming a member of the mycusini Club, users access exclusive advantages, including the capacity to create personalized 3D items and remain informed on the latest templates. Despite its advanced capabilities, the mycusini 2.0 retains a compact size, suitable for kitchens of all dimensions.

To sum up, the mycusini 2.0 seamlessly melds technological advancement with culinary ingenuity, offering both beginners and seasoned chocolatiers the resources to delve into the world of 3D chocolate printing and produce unique chocolate delights tailored to their preferences and fantasies.

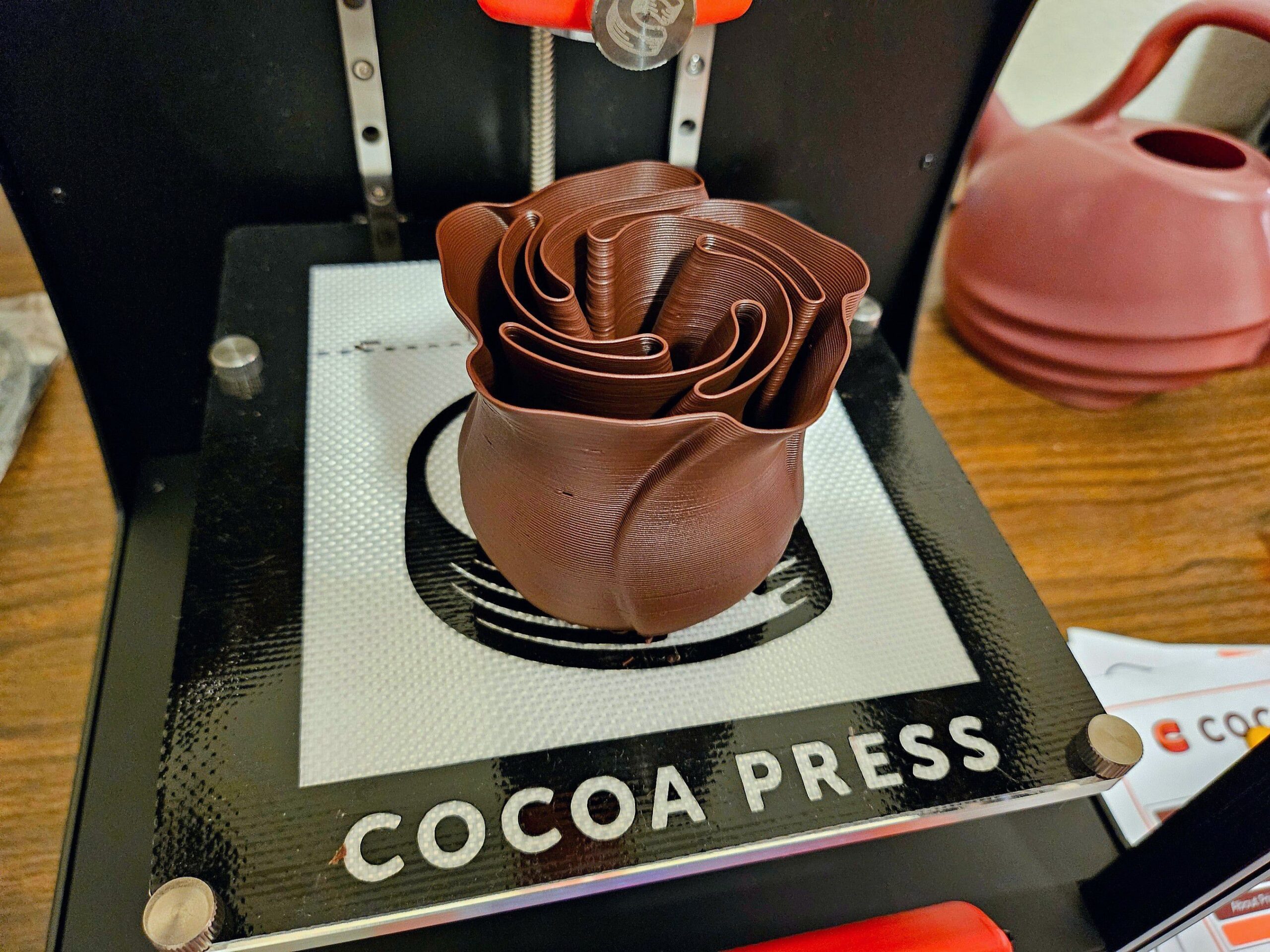

Cocoa Press

Cocoa Press embodies the epitome of chocolate 3D printing, melding creativity, technical expertise, and a passion for sweets. Here is an elaborate examination of the most recent iteration:

Chef showcases a sleek, culinary-safe stainless steel framework, guaranteeing resilience and cleanliness. The construction chamber boasts double-glazed entrances, upholding ideal temperature and moisture levels. An insulated enclosure heightens accuracy throughout the printing procedure. The all-metal stepper motorpropelled extruder permits exact temperature regulation and uniform chocolate flow. A vapor compression cooling mechanism ensures swift solidification of each tier. Temperature detectors spread across the extruder uphold precision.

Chef’s user-friendly touchscreen interface streamlines operation. Users have the ability to personalize designs, modify configurations, and track progress effortlessly. Chef has the capability to produce elaborate chocolate sculptures, personalized confections, and elaborate motifs. It caters to both seasoned chocolatiers and enthusiasts. Fun Fact: Chef debuted in autumn 2020, bringing joy to chocolate aficionados globally. To sum up, Cocoa Press’s Chef harmonizes culinary craftsmanship with state-of-the-art technology, enabling chocolate fanatics to revel in bespoke, 3D-printed pleasures.

Bocusini

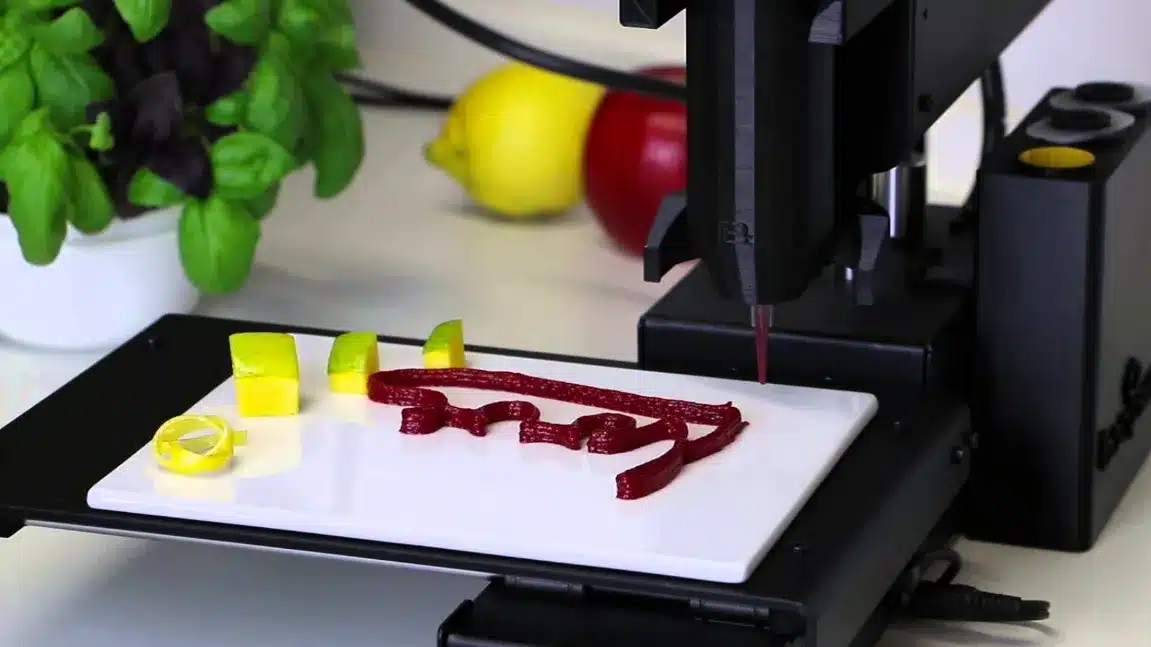

Bocusini represents cutting-edge 3D culinary technology that enables passionate food enthusiasts and professionals to fabricate unique, consumable creations. Here are the essential highlights:

Procusini crafted by Bocusini: Procusini presents a sophisticated, user-friendly 3D culinary printing solution perfect for a variety of kitchen environments such as resorts, food service, pastry shops, and sweet shops. Its expertise lies in creating intricate and premium chocolate patterns, suitable for both smallscale designs with the Procusini mini and customizable options with the Procusini 3D Schokodrucker and Procusini Research.

Quality Guarantee: Procusini upholds top-caliber standards with premium components and precise German craftsmanship, supported by a one-year warranty.

Effortless Operation: The hassle-free Plug’n’Play system of Procusini demands zero upkeep, allowing users to commence 3D printing promptly and manage and sanitize it with simplicity.

Rapid Output: Through the Procusini Performance Stack, users can generate 150 to 300 chocolate patterns daily, selecting from more than 1,000 templates to delight clients with inventive, personalized confections.

Bocusini created by Natural Machines: Bocusini, developed by Natural Machines, employs paste deposition technology to fabricate edible components from paste supplies. It offers a building field of 150 × 150 × 130 mm.

Altered Printrbot Metal Simple: The Bocusini utilizes a modified Printrbot Metal Simple, showcasing a warmed 3D food printing head, WiFi command, and a user-friendly interface. It is available in Junior and Pro variants with diverse print capacities.

BeeHex Chef 3D

BeeHex Automation, based in Columbus, Ohio, is an innovative creator specializing in state-of-the-art pastry automation devices. Their specialty lies in dessert embellishment, and they have crafted a collection of decorating machines that redefine our approach to sugary delights. One of their extraordinary creations is the Chef 3D.

The Chef 3D is a groundbreaking 3D printing apparatus engineered to produce personalized pizzas. Yes, you understood that correctly—pizza manufacturing! Envision having a pizza molded like a heart, a celestial body, or even your preferred superhero symbol. With the Chef 3D, this is achievable. Users can instruct the Chef 3D to produce any pizza contour they wish. The printer carefully dispenses dough, sauce, and cheese stratum after stratum, culminating in a visually attractive and delectable personalized pizza.

Originally aimed at professional settings, the Chef 3D discovered its niche in pizzerias. However, its potential extends beyond pizza. Picture implementing this technology to other edibles—customized sweets, savory courses, and more. The Chef 3D is immensely effective, crafting a pizza masterpiece in merely 60 seconds. Postprinting, you effortlessly insert it into the oven, and presto—a fresh, exclusive pizza materializes.

BeeHex amassed a remarkable $1 million in kickstart funding to roll out the Chef 3D with initial food industry clientele. Their aspiration is to transform food personalization and infuse ingenuity into the culinary realm. To summarize, the BeeHex Chef 3D is not just a pizza printer; it’s a delightful fusion of technology, gastronomic artistry, and countless opportunities. Whether you’re a pizza aficionado or a culinary enthusiast craving novelty, the Chef 3D pledges a glimpse of the future on your platter.