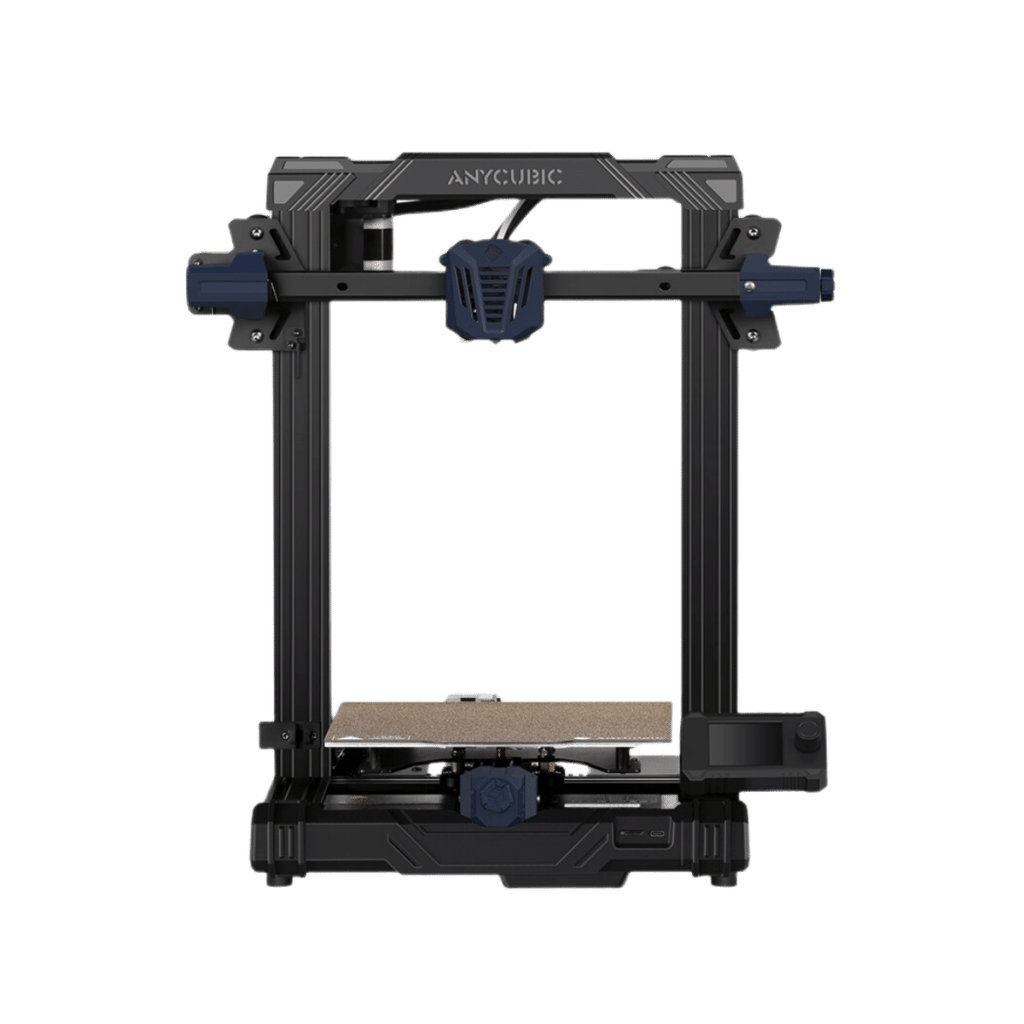

AnyCubic Kobra Go 3D Printer is a magnificent machine with solid development and durable chassis. The 3D printer adopts top-notch specifications in the form of 25-point automatic leveling, 220x220mm printing platform, 2.4-inch LCD display, 100mm/s speed, Bowden extruder for faster printing, multiple filaments, and an aluminum alloy build frame.

Build and Construction

Physically, the printing machine reflects a simple appearance and solid build with a high-grade aluminum alloy material. The front side of the integration hosts a 2.4” LCD panel. With Fused Deposition Modeling technology, you will capture a 220x220x250mm printing platform. In terms of physical dimensions, the AnyCubic printer measures 445x443x490mm and weighs only 7.3kg.

Display

Coming as an additional part, there is a 2.4” LCD touchscreen with high-resolution and multi-touch interaction. Like many other printing devices, it also endeavors to offer real-time printing information and other crucial data for excellent productivity. It is easy to use when it comes to controlling printing operations.

Printing Speed

The printing speed is something significant to analyze about 3D printers. In the case of the AnyCubic Kobra Go 3D Printer, enthusiasts will capture 100mm/s along with 0.05-0.3mm layer thickness. Users will also find a 220x220x250mm working area to transform imagination into reality. Along with the FDM modeling technology, the 3D printing machine comes with a 0.4mm nozzle, 1.75mm filament diameter, and spring steel magnetic build plate.

Leveling

The latest printing machine integrates an auto-leveling system similar to the original Kobra. The self-developed AnyCubic LeviQ system ensures excellent platform leveling with 25 points to make printing easy and precise. It dares to manifest easy leveling of the hotbed to let people develop accurate prints with high-end precision.

Connectivity

When we come to connect the printer to external devices, the machine supports users to submit data Micro SD card and USB-C port. Also, it advocates various filaments, including TPU, WOOD, PETG, NYLON, PLA, PLA+, and PC, along with a Cura slicer.